What is Lean Six Sigma and How to apply it?

21st Jul, 2025Many organizations struggle with rising operational costs, inefficient processes and inconsistent quality, all of which impact profitability and customer satisfaction. Lean Six Sigma offers a powerful solution by combining two time-tested methodologies—Lean, which focuses on eliminating waste and improving flow and Six Sigma, which aims to reduce variation and defects. Together, they create a structured, data-driven approach to process improvement that delivers measurable results. From manufacturing to services, businesses across industries use Lean Six Sigma to streamline operations, enhance quality and build a culture of continuous improvement. In this blog, we’ll explore what Lean Six Sigma is, why it matters and how you can apply its tools and principles to drive meaningful change in your organization.

.

WHAT IS LEAN SIX SIGMA?

Lean Six Sigma is a powerful process improvement methodology that blends the principles of Lean and Six Sigma to help organizations operate more efficiently and deliver higher quality outcomes. It is widely practiced and supported by structured certification programs such as Lean Six Sigma Yellow Belt, Green Belt and Black Belt, which equip professionals with the tools to drive data-based, measurable improvements.

Lean, pioneered by Toyota, focuses on eliminating waste and improving workflow by streamlining processes and removing non-value-adding activities. Six Sigma developed by Motorola aims to reduce process variation and defects through data-driven analysis and statistical tools.

When combined, Lean and Six Sigma provide a structured, results-oriented approach that helps businesses minimize errors, cut costs and enhance customer satisfaction. This integrated method is widely used across industries such as manufacturing, healthcare, logistics, IT and services.

.

.

DIFFERENCE BETWEEN LEAN AND SIX SIGMA

| Aspect | Lean | Six sigma |

| Origin | Toyota Production System (Japan) | Motorola (USA) |

| Primary Focus | Eliminating waste and improving flow | Reducing variation and defects |

| Approach | Process speed and efficiency | Data-driven quality improvement |

| Tools | 5S, Value Stream Mapping, Kaizen, Kanban | DMAIC, Control Charts, Fishbone, 5 Whys |

| Key Goal | Deliver faster and more efficiently | Deliver with high precision and low defects |

| Customer | Maximizes value by removing non-value tasks | Ensures consistent quality to meet expectations |

| Metric | Time, flow, waste levels | Defects per million opportunities (DPMO), Sigma level |

| Team Involvement | Broad workforce engagement | Typically led by certified project teams |

.

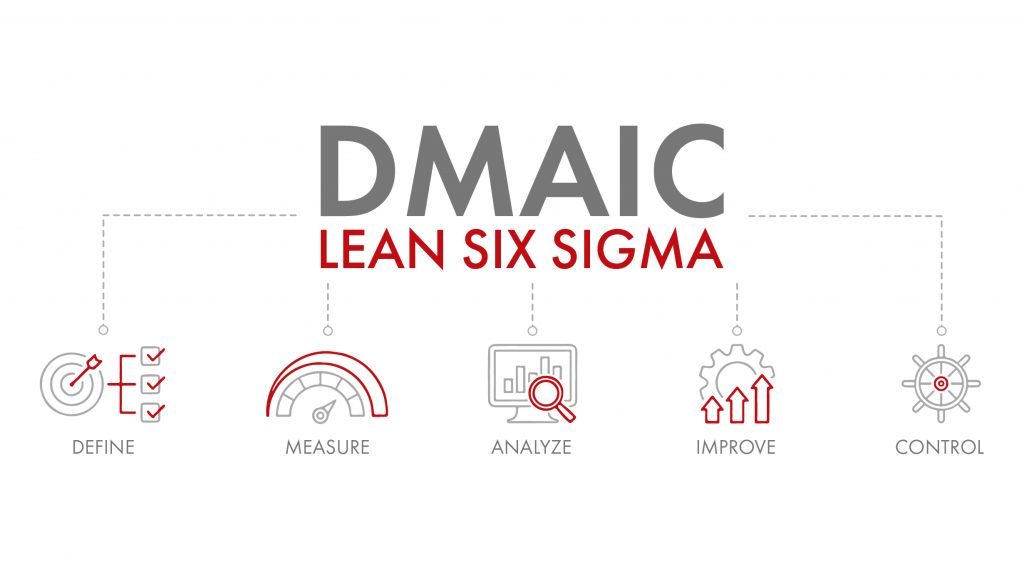

Understanding the DMAIC Framework

Lean Six Sigma’s DMAIC framework is core approach to solving problems and improving processes. DMAIC stands for Define, Measure, Analyze, Improve and Control. It is a structured step-by-step method that helps teams identify the root cause of issues, implement effective solutions and ensure those improvements last. This approach is used across industries because it brings clarity, discipline and measurable outcomes to improvement efforts. Each phase serves a specific purpose and together they form a continuous improvement cycle:

- Define: This phase focuses on understanding the problem and setting clear objectives. It involves identifying the issue, understanding its impact on customers and business and outlining what needs to be achieved. The team defines the project scope, goals, timelines and key stakeholders involved.

- Measure: This involves gathering data to understand the current state of the process. The team collects accurate and relevant data to measure how the process is performing. Establishing a performance baseline is crucial to identify gaps and areas that need improvement.

- Analyze: Once data is collected, the Analyze phase helps the team determine the root cause of the problem. Instead of guessing, the team uses structured tools such as cause-and-effect diagrams, Pareto charts and the 5 Whys method. The focus here is on understanding why the problem is happening.

- Improve: In this phase, the team develops and tests solutions that address the identified root causes. Improvements are implemented in a controlled way to evaluate their impact. This could involve process changes, updated lean training or equipment upgrades.

- Control: It is the phase where the improvements are stabilized and monitored over time. The goal is to prevent the problem from recurring. The team creates standard procedures, defines responsibilities and puts checks in place to maintain the gains.

DMAIC is not just a process, it is a mindset that promotes clarity, accountability and continuous learning. By using this approach, teams move beyond temporary fixes and address the real causes behind performance issues. It empowers organizations to make smarter decisions, reduce waste and build processes that consistently deliver value.

.

HOW TO APPLY LEAN SIX SIGMA

Implementing Lean Six Sigma methodology is a structured that integrates data-driven problem-solving, team collaboration and continuous learning. While the methodology originated in manufacturing, its relevance spans engineering services, healthcare, logistics, IT, finance and other industries where quality, efficiency and customer satisfaction are critical.

The application begins with identifying a process-related challenge that impacts cost, delivery, quality or customer experience. Once the improvement area is confirmed, a cross-functional team, often comprising process owners, engineers and certified Six Sigma professionals & follows the DMAIC framework.

Alongside technical analysis the success of Lean Six Sigma also relies on clear documentation, structured reviews, internal trainings and sustained accountability. For example, of an engineering design firm experiencing delays and rework in delivering customized 3D CAD models to clients.

.

1. DEFINE THE PROBLEM AND PROJECT SCOPE

The first step is to clearly define the problem and align it with business and customer priorities. This phase involves identifying what’s going wrong, how it’s affecting performance and what outcomes are expected. In our example, the firm faced repeated design revisions, leading to delivery delays and lower client satisfaction. The project team sets a focused goal: to reduce the average number of revision cycles from 4 to 2 within 60 working days.

Documentation is essential at this stage to capture the project scope, responsibilities, key stakeholders and expected benefits. Teams often prepare a Project Charter and use SIPOC diagrams to visualize the process flow from inputs to customer outputs. Voice of the Customer (VOC) data—gathered from surveys or feedback—is used to validate client expectations and highlight service gaps.

Key outputs of this phase include:

- A defined project charter with goals and scope

- SIPOC diagrams to outline upstream and downstream activities

- VOC summaries and stakeholder alignment

.

2. MEASURE THE CURRENT PROCESS

In the Measure phase, the team gathers data to understand how the process currently performs. This includes mapping each step in the workflow, quantifying cycle times, identifying points of delay and documenting where errors or rework occur. In the engineering firm’s case, data showed that a high number of design files were being sent back by clients due to unclear assumptions or inconsistent formatting.

The team sets up a measurement plan to ensure that only relevant, reliable data is collected. Process maps are created to trace how a design request moves from requirement intake to final delivery. This allows the team to quantify the baseline performance and pinpoint areas with the greatest variation.

Typical measurement activities may involve:

- Capturing turnaround times and revision counts by team

- Tracking internal review durations and client rejection reasons

- Creating process maps to visualize handoffs and delays

.

3. ANALYZE TO IDENTIFY ROOT CAUSES

Once the data is collected, the Analyze phase focuses on identifying the real root causes behind process inefficiencies. Instead of making assumptions, the team uses structured tools such as 5 Whys, Fishbone diagrams and Pareto charts to discover why the issue is occurring. In this scenario, analysis reveals that client specifications are often misinterpreted due to vague requirement formats and internal review practices differ between teams—resulting in inconsistent quality.

This phase also involves cross-checking documentation quality, interviewing team members and reviewing actual defect samples. Often, root causes are not due to a single failure but a combination of small gaps across communication, documentation and training.

Analysis may lead to findings such as:

- Lack of a standardized format for requirement intake

- Non-uniform review guidelines leading to rework

- Gaps in design knowledge among newer team members

.

4. Improve the Process

The Improve phase is where the team develops and tests practical solutions to address the identified root causes. Based on the findings, the engineering firm introduces a standardized intake form that captures all essential client requirements, technical constraints and reference models upfront. Internal review checklists are created to guide all design reviewers with a consistent evaluation framework.

Additionally, the firm sets up targeted training for junior designers covering drawing standards, client interaction protocols and frequent error types. A pilot project using these changes shows a significant reduction in revision cycles and faster client approvals.

Improvements are typically supported by:

- Updated work instructions and visual SOPs for design reviews

- A central library of reusable, error-free design templates

- Structured training modules with hands-on simulation sessions

.

5. CONTROL AND SUSTAIN THE GAINS

Once improvements are implemented, the Control phase ensures that results are sustained over time. This involves creating systems for ongoing monitoring, establishing responsibilities and impacting improvements into standard operations. In our engineering case, new SOPs are version-controlled and made accessible through a shared platform. Regular refresher trainings are conducted to keep design standards sharp across teams.

The firm introduces weekly performance reviews with real-time dashboards tracking revision rates, on-time deliveries and client feedback scores. Periodic internal audits are also scheduled to verify compliance with new procedures and capture early signs of deviation. These governance mechanisms ensure that improvements ae done and the team remains aligned with quality goals.

Key Control Measures Include:

- Real-time performance dashboards with revision trend analysis

- Weekly audit cycles and review meetings with documented findings

- Scheduled refresher trainings and SOP compliance checks

By following this structured approach, organizations can go beyond temporary fixes and build lasting, high-performance processes. Lean Six Sigma not only addresses visible inefficiencies but also drives cultural change encouraging teams to think critically, make decisions based on data and stay committed to continuous improvement. Whether in engineering, healthcare or finance, the same disciplined methodology can be adapted to unlock operational excellence and deliver lasting value to both customers and the business.

.

BENEFITS OF IMPLEMENTING LEAN SIX SIGMA

Implementing Lean Six Sigma brings clear improvements in cost, quality, delivery and customer satisfaction. It helps organizations shift from reactive fixes to proactive, long-term solutions. The impact goes beyond short-term savings and leads to stronger teamwork, better decision-making and greater stability in operations.

Lean Six Sigma improvement tools equips businesses with reduced waste, improve quality and build processes that consistently deliver value. Here’s how it helps:

- Better Process Efficiency: Lean Six Sigma helps teams identify steps that don’t add value and slow down work. By removing delays, duplication and unnecessary tasks, organizations can reduce turnaround time, simplify workflows and use resources more effectively. This leads to smoother operations, fewer bottlenecks and faster response times. Teams spend less time troubleshooting and more time delivering results.

- Lower Operating Costs: Reducing errors and waste means fewer reworks, less scrap and fewer customer complaints. These improvements cut both visible and hidden costs. Many businesses see strong financial benefits within a few months of starting Lean Six Sigma projects. It allows companies to redirect resources toward growth initiatives instead of fixing recurring problems.

- Higher Quality Output: The focus on reducing variation ensures that products and services are delivered consistently. Whether it’s a product or a customer request, fewer errors mean fewer issues, better results and higher trust in your brand. Stable processes also reduce inspection efforts, avoid last-minute corrections and enhance reliability across every function.

- Smarter Decision Making: Instead of acting on guesswork, teams use data to understand problems and measure success. Tools like root cause analysis and control charts help leaders identify trends, fix recurring issues and manage risks with confidence. This creates a fact-based culture where decisions are informed, timely and aligned with business goals.

- Better Customer Experience: Faster service, fewer errors and consistent quality all lead to happier customers. Lean Six Sigma helps align internal efforts with what customers really care about, improving satisfaction and building long-term loyalty. Meeting expectations consistently strengthens relationships and sets your business apart from competitors.

- Stronger Team Involvement: People across the organization get involved in solving problems and improving their work. With the right training and support, teams gain practical skills, become more engaged and take ownership of results. This fosters a continuous improvement culture and helps reduce resistance to change over time.

- Long-Term Growth and Flexibility: Organizations that apply Lean Six Sigma build systems that are easier to manage and scale. They are more prepared to adapt to change, meet customer demands and stay ahead of competition. The method supports long-term planning, innovation and agility in both stable and evolving business environments.

Lean Six Sigma is a practical and proven approach that helps organizations improve efficiency, reduce errors and deliver consistent quality. By combining the strengths of Lean and Six Sigma, businesses can identify real problems, fix them at the root and sustain the improvements over time. It’s not just about cutting waste or solving defects, it’s about building a culture where teams work smarter, make decisions based on data and continuously improve the way they operate. With the right tools, training and commitment, Lean Six Sigma enables long-term growth, better customer satisfaction and stronger, more flexible operations across any industry.

.

How 4C Helps organization Implement Lean Six Sigma Implementation?

At 4C Consulting, we provide end-to-end Lean Six Sigma implementation support tailored to your industry needs. Our experienced consultants help organizations drive measurable improvements through expert-led training, hands-on project execution, effective tool deployment, and guidance toward certification. With a track record of serving over 45 clients, delivering 1300+ training hours, and facilitating 60+ professional certifications, we ensure results that are both impactful and sustainable. By integrating Total Quality Management (TQM) principles and cost-effective strategies, 4C helps businesses enhance process efficiency, reduce waste, and boost customer satisfaction. Reach out to start your Lean Six Sigma journey with us.

Frequently Asked Questions:

Lean Six Sigma is a process improvement methodology that combines Lean (which focuses on eliminating waste) and Six Sigma (which focuses on reducing variation and defects). Together, they help organizations improve efficiency, quality, and customer satisfaction through a structured, data-driven approach.

Lean Six Sigma uses a belt-based hierarchy to define levels of expertise, similar to martial arts. The 6 common belts are:

- White Belt: Entry-level awareness of Lean Six Sigma principles; often for staff who support projects indirectly.

- Yellow Belt: Basic understanding of tools and processes; supports project teams with data collection and analysis.

- Green Belt: Intermediate level; leads smaller projects and assists Black Belts with data analysis and improvements.

- Black Belt: Expert level; manages cross-functional improvement projects and mentors Green Belts.

- Master Black Belt: Strategic level; trains and coaches Black Belts, leads enterprise-wide initiatives, aligns projects to business goals.

- Champion: Typically, a senior executive who sponsors Lean Six Sigma efforts and ensures alignment with organizational strategy.

The Six Sigma process is built around the DMAIC framework, which stands for:

- Define:Identify the problem and project goals

- Measure: Collect data to understand current performance

- Analyze: Identify root causes of issues

- Improve: Develop and implement effective solutions

- Control: Sustain improvements through monitoring

(Note: Though often called "6 Sigma," the DMAIC process has five steps.)

1. Focus on the Customer

2. Analyze the Value Stream

3. Eliminate Waste and Non-Value Activities

4. Engage and Involve Stakeholders

5. Ensure Continuous Improvement and Flexibility

Lean focuses on improving process flow by removing non-value-adding activities (waste), while Six Sigma targets process accuracy and defect reduction. Lean brings speed and efficiency to Six Sigma’s precision and problem-solving, making the combined approach more powerful and balanced.

Yes, a Lean Six Sigma certification is highly valuable. It equips professionals with structured problem-solving, data analysis, and process improvement skills that are applicable across industries like manufacturing, healthcare, IT, and finance. Certified individuals often see higher career growth, better job roles, and increased earning potential. For organizations, hiring certified professionals supports a culture of continuous improvement and operational excellence